DRIVETRAIN

Our drivetrain consisted of two brushed DC motors each driving a scooter wheel, two casters for stability, and an L298N motor driver to control the motors. A CAD rendering of the drivetrain is shown below.

All components of the chassis are lasercut from 1/4" thick Duron sheets and glued together. The batteries are mounted to the chasses via velcro strips, the motor is mounted using motor mounts, and the wheels are supported on both sides to reduce the bending moment on the motor. A helical shaft coupler connects the wheel shaft to the motor shaft to account for any misalignments. The two casters are mounted using 1/4" bolts and nuts to the chassis.

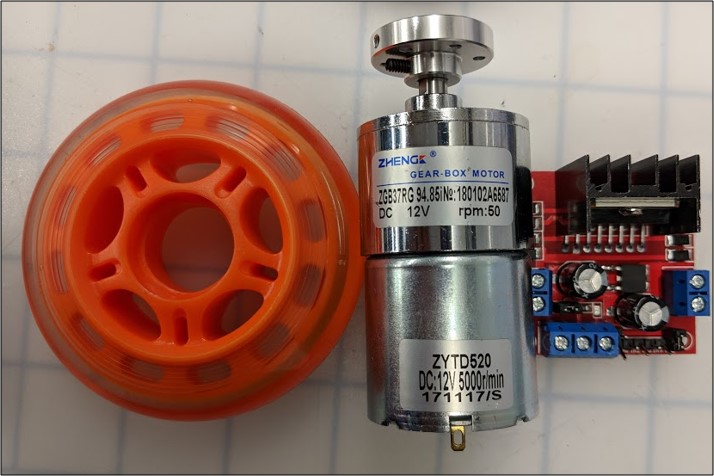

We chose two Zheng ZGB37RG from the ME 210 lab stockroom to drive the wheels. These motors were chosen because of their high torque output. Initial qualititative testing proved that these motors would run fast enough and were powerful enough for the robot. The L298N motor driver was also obtained from the lab stockroom.

Below is our wiring diagram for the drivetrain. The 12V going into the motor driver comes from a voltage regulator set at 12V. The Teensy LC is powered by the 5V VCC terminal on the driver.