Hot surface ignition of fuel sprays

The accidental ignition of liquid fuels is an industrial safety concern due to the storage and transport of pressurized flammable liquids near components at elevated temperatures. We consider a liquid n-dodecane fuel spray impinging on a hot surface, undergoing thermal ignition. At high surface temperatures, the interaction of the spray with the hot surface is governed by the Leidenfrost effect, resulting in inelastic reflection of impinging droplets. Large-eddy simulations are employed with finite-rate chemistry, and low-temperature ignition chemistry is considered. An Eulerian-Lagrangian approach is taken to the describe the spray dynamics. The secondary flow resulting from the spray impingement in the form of a toroidal vortex is shown to enhance scalar mixing. Low-temperature ignition within the vortex significantly precedes high-temperature ignition near the wall and subsequent rapid flame propagation. This work provides fundamental understanding of the physical phenomena involved in the thermal ignition of impinging sprays in different temperature regimes toward the goal of improved industrial safety.

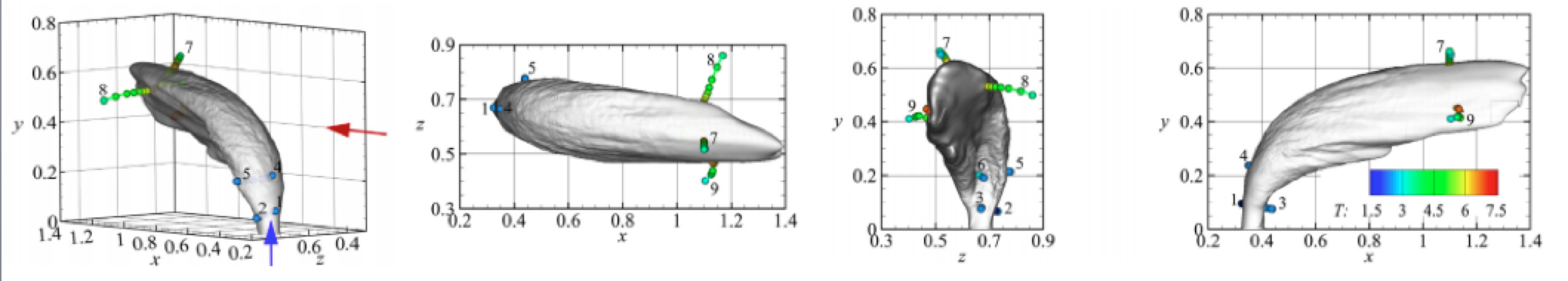

Temporal evolution of the hot surface ignition process of an impinging fuel spray. The instantaneous stoichiometric Bilger mixture fraction isosurface is colored by radial distance from the central axis for visual contrast. The temperature isosurface T = 1500 K is shown in gray to represent the flame. Results are shown in half of the domain to better illustrate the structure of the flow field.

Flame blow-out

In order to increase combustion efficiency and reduce pollutant emission, modern gas turbine combustors are required to work under fuel-lean conditions, and even close to the lean blow-out (LBO) limit, where the flames are usually highly unsteady, accompanied by local extinction and reignition events, which may lead to complete flame extinction. Therefore, the understanding of flame blow-out is of fundamental importance for practical applications. In particular, the reliable prediction of blow-out limits is of direct relevance for the design of gas turbine combustors, afterburners, and other propulsion systems relevant to the Air Force.

The objective of this research is to investigate the underlying physical mechanisms and parameters that control the transient blow-out dynamics of turbulent swirl-stabilized non-premixed flames. To this end, different LBO-triggering strategies are employed and high fidelity large-eddy simulations are performed at different operating conditions. The Model Evaluation and Development Strategy (MEDS) framework is developed for the assessment and evaluation of turbulent combustion models in the context of blow-out prediction.

Adaptive combustion model

Despite significant progress in combustion modeling, considerable challenges remain in the mathematical description and the simulation of chemically reacting turbulent flows. Usually the selection of an appropriate combustion model for the numerical prediction of reacting flows is carried out using expert knowledge or experimental data, while the computational cost that is associated with the available combustion models introduces a further constraint. By addressing these issues, the Pareto-efficient combustion (PEC) framework has been developed, which can be applied to complex reacting flows uder consideration of user-specific inputs about the quantities of interest, desired simulation accuracy and computational cost given a set of combustion models. Based on those constraints, PEC has the ability to dynamically select the appropriate local combustion model assignment.

Applying the PEC framework to complex systems such as gas turbine engines and rocket thrust chambers allows for the accurate estimation of performance-defining parameters with a minimal cost. Quantities of interest for the engine design such as CO and CO2 emissions, NOx formation, wall heat fluxes are included in the PEC framework allowing for precise yet computationally efficient predictions.

Unsteady flamelet model

An a priori analysis of the flamelet model for diffusion flames is conducted to systematically assess model assumptions that are associated with the asymptotic expansion, the omission of higher-order expansion terms, the consideration of preferential diffusion effects, and the one-dimensional flamelet representation. A balance analysis of the temperature flamelet equation is conducted to quantify contributions in flame-aligned and flame-orthogonal directions. Consistent with the flamelet assumption, it is shown that terms arising from scalar diffusion, heat-release, and species-diffusion induced enthalpy flux are the dominant contributions, while the flame-aligned preferential diffusion promotes entrainment of heat into the flamelet structure.