|

A

self-priming, roller-free, miniature, peristaltic pump operable with a

single, reciprocating actuator |

|

Viktor

Shkolnikov, John Ramunas, Juan G. Santiago |

|

We

designed a miniature self-priming peristaltic pump actuated with a single

linear actuator. The structure can be

manufactured using conventional materials and methods. The pump is tolerant

of bubbles and particles and can pump liquids, foams, and gases. We explore

designs actuated by a motor (in depth) and a shape memory alloy (briefly). We also briefly present a manually actuated

version. Figure

1 shows the motor actuated version. The

pump consists of a Delrin acetal plastic body with two integrated valves, a

flexible silicone tube, and an actuator. Pumping is achieved by cam-driven

motion of a lever acting on a section

of the tube (see caption). This design offers a linear dependence of flow

rate on voltage in the range of 1.75–3 V. Flow rate decreases from 780

μl/min with increasing back pressure up to the maximum back pressure of

48 kPa. At 3 V and minimum back pressure, the pump consumes 90 mW. |

Motor-driven pump

|

|

|

Figure 1. (a) Pump driven by a gear motor shown in phase (1) of pumping cycle. The pumping chamber and inlet and outlet connections are a single piece of commercially available silicone tubing. Arrows indicate flow direction. The pump (with motor) is 8 × 22 × 35 mm, weighs 3.6 g, and consists of four parts: motor, cam, pump body, and tube. (b) Schematics showing phases of the pumping cycle. Black arrows indicate flow direction. Phase 1: Cam (not shown) rotation pushes down on the plunger arm, pinching the tubing and creating upstream valve. Phase 2: Further motion of the plunger arm rotates the plunger clockwise (about the protrusion of upstream valve), compressing the pumping chamber. Increased pressure in the pumping chamber causes the downstream burst valve to open, expelling fluid from the pumping chamber. Phase 3: The downstream valve closes as pressure is reduced in the pumping chamber. As the cam rotates further, it allows the plunger arm to spring upward, and the elasticity of the tubing and line pressure open the upstream valve. The pumping chamber draws liquid through the now-open upstream valve into the pumping chamber. |

|

Video of Motor Actuated Pump Here |

|

|

|

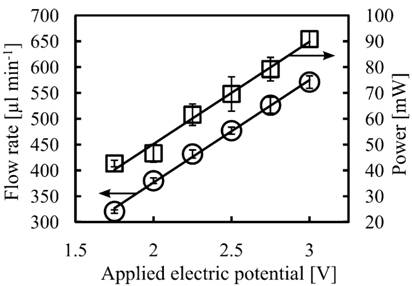

Figure

2. Flow rate (○) and power (□) measured versus driving voltage

with minimal back pressure. There is a linear relationship (R2

= 0.998) between flow rate and voltage, which allows for convenient voltage

control of flow rate. There is also a linear relationship (R2

= 0.987) between power consumption and driving voltage. Uncertainty bars are

±1.0 standard deviation from the mean across N = 5 repetitions. |

|

|

|

Figure

3. Pump flow rate (○) as a function of back pressure. Flow rate

decreases gradually with increasing back pressure (from a maximum value of

780 μl/min), as expected. The motor was operated at 3 V, and the maximum

pressure achieved was 48 kPa. The inset plot shows thermodynamic efficiency

(□) as a function of back pressure. A maximum efficiency 0.3% is

reached at a back pressure of 30 kPa. |

|

|

|

Figure 4.

Breakdown of power consumption by component. The total power consumed by pump

at 3 V and 30 kPa back pressure (the maximum thermodynamic efficiency point)

is 100 mW. The motor and gearbox consume most of the power (61%); compression

of the tubing consumes 26%; and compression of elastic joints and movement of

the plunger arm (pump body) 7%. Additional power consumed to pump deionized

water accounts for only 6% of total power. The inset shows a plot of flow

rate per power consumed versus driving voltage against minimal back pressure.

Flow rate per power decreases with driving voltage, leading to lower

efficiency at higher voltages. Uncertainty bars are ±1.0 standard deviation

from the mean (N = 5). |

|

Table

1. Motor-driven pump flow rate performance with selected media. |

|

|

SMA and manually actuated versions of the pump

|

The shape memory alloy actuated design is shown in Figure 5a. This design offers a 5-fold size and 4-fold weight reduction over the motor design, higher maximum back pressure, and substantial insensitivity of flow rate to back pressure at the cost of lower power efficiency and flow rate. The manually actuated version (Figure 5b) is simpler and appropriate for applications unconstrained by actuation distance. |

Table 2. Summary of figures of merit for

motor and SMA wire actuated pump designs.

|

|

|