Plastics life cycle

Plastic formation

In order to eliminate the use of petrochemicals in plastic generation, polymers are being derived from natural and renewable sources that are readily available. Bio-resources are used to form polymers identical to those currently used or design new polymers with similar properties. Extensive control over the polymerization process is required to produce polymers with specific properties.5 These polymers must enter the market and compete with fossil-fuel derived polymers from a technical and commercial standpoint. Despite these obstacles, a major advantage is that new polymers can be designed as either biodegradable or compostable.

PolyLactic Acid (PLA) is derived from the fermentation of dextrose, which is sourced from corn or any starch-rich feedstock, and is either biodegradable or compostable. PLA's applications include packaging, disposable goods, durable goods, bottles, film, and fibers.6

Polyhydroxyalkanoates (PHS) is an alternative biopolymer produced by the bacterial fermentation of renewable feedstocks such as glucose, fructose, and vegetable oil. PHS is biodegradable and used for water bottles along with other niche applications in various industries such as medicine or agriculture.6

Thermoplastic Styrenic Elastomers (TPS) are formed from starch polymers which are found in corn and are biodegradable or compostable. Uses of TPS include films, rigid materials (plates, cutlery), packaging, and foams.6

While these three alternatives to hydrocarbon-derived polymers are derived from renewable resources and are biodegradable or compostable, they are not preferred over the standard polymers due to their increased expenses and extensive production processes.7

Plastic disposal

Most plastics are currently treated as single-use and are discarded into landfills or the environment after use. However, other options include recycling, reprocessing, thermal destruction, chemical up-cycling, and chemical recycling.

Disposal of plastics into landfills and the environment is the most common and harmful. In 2019, 27.0 million tons of the 38.7 millions tons of plastic materials in municipal solid waste generated was discarded in landfills.8 The slow degradation of plastics has allowed the massive accumulation of plastics. While thermal destruction is an alternative, the associated CO2 emissions contribute to the release of GreenHouse Gases into the atmosphere. For example, in 2015, 96MtCO2 was emitted contributing to the total GreenHouse Gas emission.9

While the other three methods, recycling/reprocessing, chemical upcycling/recycling, and polymer depolymerization, are aimed at expanding the lifetime of single use-plastics, there are serious obstacles preventing their effectiveness. Plastic waste must be sorted as polymers require different treatments based on their monomers and any additives used to enhance the material. Several methods to separate different plastics involve manual sorting, triboelectrostating separation, density difference based separation, selective dissolution, and floatation techniques.10

Recycling and reprocessing

Recycling plastics often involves their mechanical destruction which produces polymers with diminished properties. As a result, recycled polymers must be mixed with new polymers before being reconstructed into a plastic.11 The process of recycling plastics is limited as secondary plastics have limited technical use and economic value.1

Chemical upcycling and recyling

Another method used to increase the lifetime of single-use plastics is through the chemical recycling of plastics into valuable products. This extends the lifetime of plastics and bypasses the problem of diminished properties when plastics are recycled.

Incorporating the solar thermo-coupled electrochemical system into the depolymerization process produces valuable light fuel and hydrogen. The process is driven by solar energy making it less expensive than the conventional pyrolysis process and requires reduced reaction temperatures making it technically feasible.12

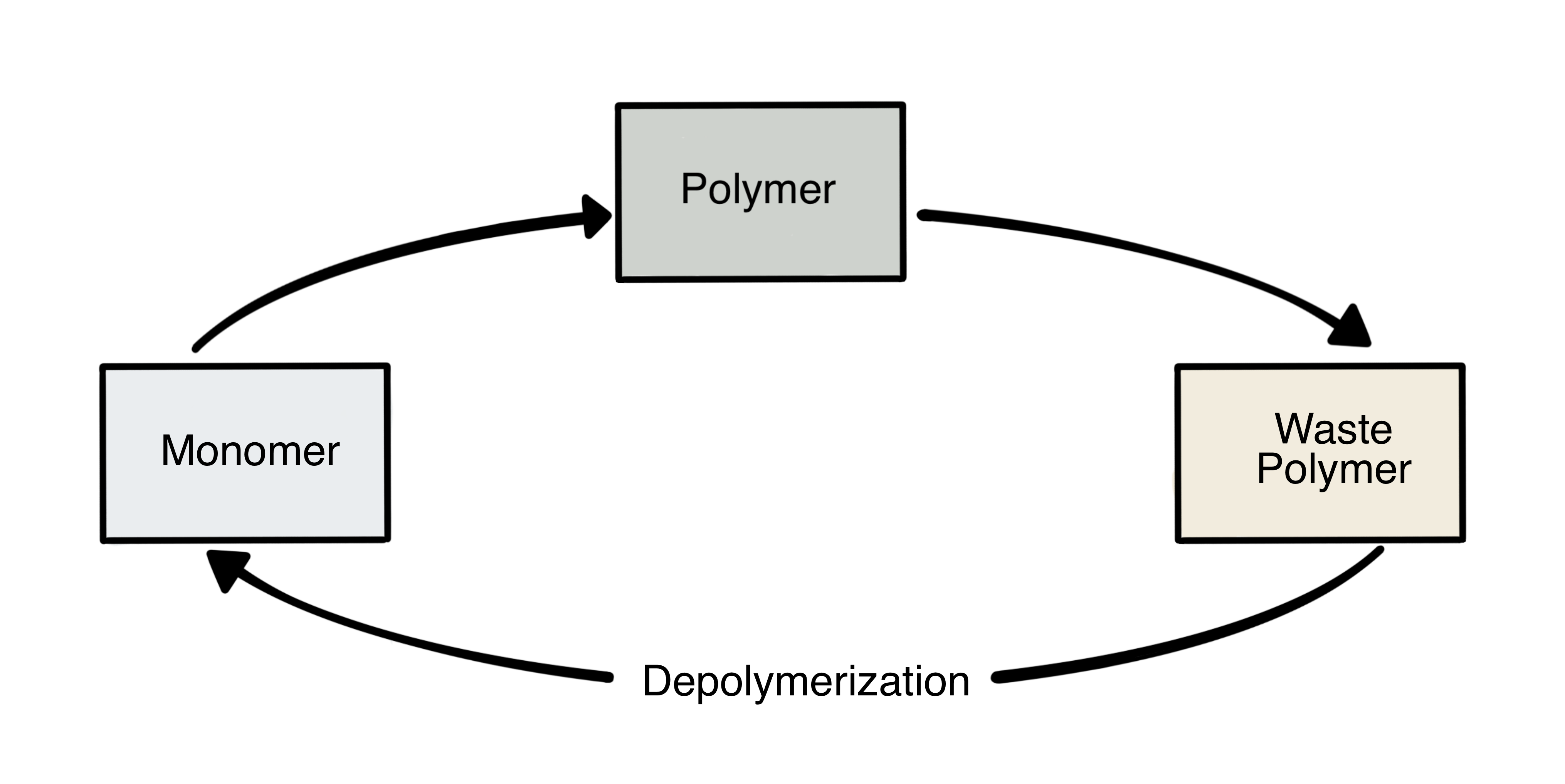

Polymer depolymerization promotes the creation of a circular plastic market where the original monomers are generated and polymerized, reducing the need to consistently form new monomers.11 However, the depolymerization process differs based on the plastic's structure and additives used. This process is extensive as it often involves pyrolysis and solvolytic routes.13 Additionally, a successful circular market would rely on proper recycling infrastructure. The low recycling rates and high expenses associated with sorting plastics reduces the economical appeal of depolymerization.11

References:

[1] Geyer, R., Jambeck, J. R., & Law, K. L. (2017a). Production, use, and fate of all plastics ever made. Science Advances, 3(7), e1700782.

[2] US EPA, O. (2017, September 12). Plastics: Material-specific data [Collections and Lists], plastics-material-specific-data.

[3] Plastic pollution facts and information. (2019, July 6).

[4] Schneiderman, D. K., & Hillmyer, M. A. (2017). 50th anniversary perspective: There is a great future in sustainable polymers. Macromolecules, 50(10), 3733-3749.

[5] Hillmyer, M. A. (2017). The promise of plastics from plants. Science, 358(6365), 868-870.

[6] Hottle, T. A., Bilec, M. M., & Landis, A. E. (2013). Sustainability assessments of bio-based polymers. Polymer Degradation and Stability, 98(9), 1898-1907.

[7] Fredi, G., & Dorigato, A. (2021). Recycling of bioplastic waste: A review. Advanced Industrial and Engineering Polymer Research, 4(3), 159-177.

[8] US EPA, O. (2017, October 2). National overview: Facts and figures on materials, wastes and recycling [Overviews and Factsheets].

[9] Zheng, J., & Suh, S. (2019). Strategies to reduce the global carbon footprint of plastics. Nature Climate Change, 9(5), 374-378.

[10] Negari, M. S., Ostad Movahed, S., & Ahmadpour, A. (2018). Separation of polyvinylchloride (PVC), polystyrene (PS) and polyethylene terephthalate (PET) granules using various chemical agents by flotation technique. Separation and Purification Technology, 194, 368-376.

[11] Korley, L. T. J., Epps, T. H., Helms, B. A., & Ryan, A. J. (2021). Toward polymer upcycling-Adding value and tackling circularity. Science, 373(6550), 66-69.

[12] Jiang, T., Zhao, X., Gu, D., Yan, C., Jiang, H., Wu, H., Wang, B., & Wang, X. (2020). STEP polymer degradation: Solar thermo-coupled electrochemical depolymerization of plastics to generate useful fuel plus abundant hydrogen. Solar Energy Materials and Solar Cells, 204, 110208.

[13] Weckhuysen, B. M. (2020). Creating value from plastic waste. Science, 370(6515), 400-401.