Rocket propulsion

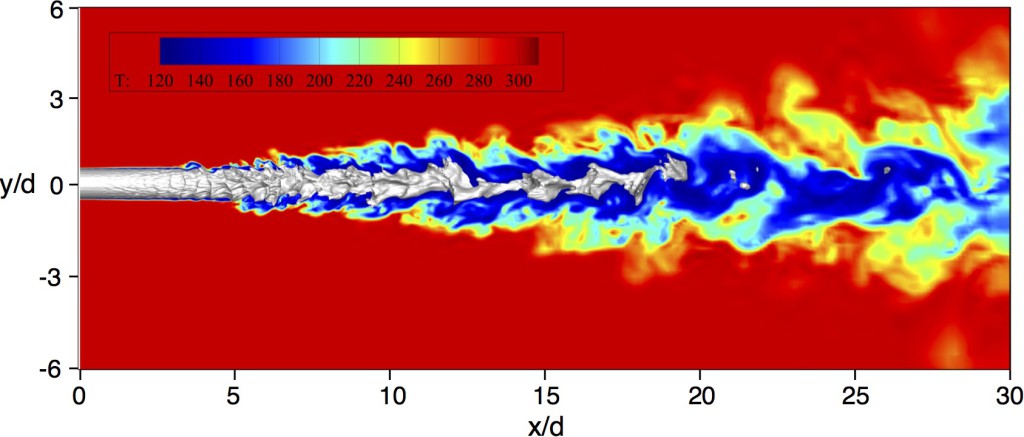

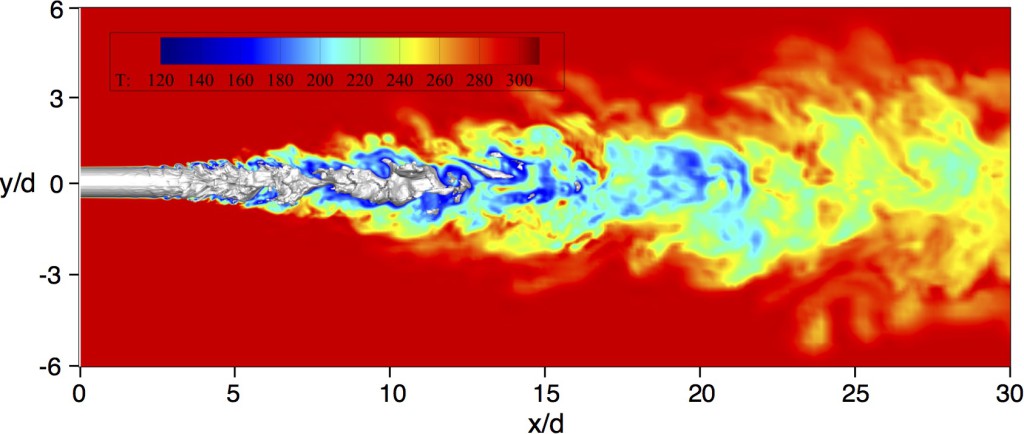

A flamelet-based combustion model is developed for the prediction of wall-heat transfer in rocket engines and confined combustion systems. To account for the impact of the flame due to convective heat loss on the wall, a permeable thermal boundary condition is introduced in the counter-flow diffusion flame configuration. The solution of the resulting non-adiabatic flame structure forms a three-dimensional manifold, which is parameterized in terms of mixture fraction, progress variable, and temperature. The non-adiabatic flamelet model is shown to accurately predict the temperature, chemical composition, and wall heat transfer. Combined with a presumed PDF-closure, the model is then applied to LES of a single-injector rocket combustor to examine effects of heat-transfer on the turbulent flame structure in rocket engines. The figure shows the predicted instantaneous temperature field at the center-plane of a rocket motor with a uni-element injector.

An entropy-stable formulation that combines high-order non-dissipative and low-order dissipative finite-volume schemes is developed to preserve the physical realizability of numerical solutions across large density gradients. A double-flux model is extended to the transcritical regime to eliminate spurious pressure oscillations associated with conventional fully-conservative schemes. The figure shows instantaneous temperature contours at the center-plane predicted by the numerical solver for cases 3 and 4 of Mayer’s cryogenic nitrogen injection experiment. Density iso-surfaces for values of 243 kg/m3 and 108 kg/m3 are shown for case 3 and Case 4, respectively.

High pressure diesel injector

Modern internal combustion engines typically operate under pressure and temperature conditions that exceed the thermodynamic critical limits of the in-cylinder gas. In diesel engines, the injection of liquid fuel at supercritical pressure and subcritical temperature into a supercritical combustion chamber introduces complex thermophysical phenomena that are currently not well understood.

These conditions may allow atomisation phenomena to be suppressed, with phase transition were to be dominated by diffusive mixing. These conditions could be described by diffuse-interface methods since sharp interfaces are no longer present. Instead of resolving liquid-vapor interfaces, these diffuse-interface methods treat fluid properties between liquid and gaseous regimes as a smooth function.

The diffused-interface method is here used with a compressible LES solver that also incorporates real-fluid effects and finite-rate chemistry, in order to simulate high pressure diesel spray combustion under various Engine Combustion Network (ECN) configurations. The ECN is an international collaboration among experimental and computational researchers from various institutions that focuses on improving scientific understanding of engine combustion.

Simulation results from previous studies that utilise this framework have successfully predicted essential spray characteristics such as spray liquid and vapor lengths, along with ignition delay and flame lift-off lengths.